The operation process of the screw air compressor starts from the suction process, and the gas experiences compression in the sealed volume between teeth and finally moves to the exhaust end.

At both ends of the compressor body, holes of a particular shape and size are respectively opened for suction and exhaust.

It is necessary to point out that Yin and Yang’s screws are formed between the body.

The volume between the two teeth of the V “shape changes with the rotation of the rotor, and its position is constantly shifting between the houses.

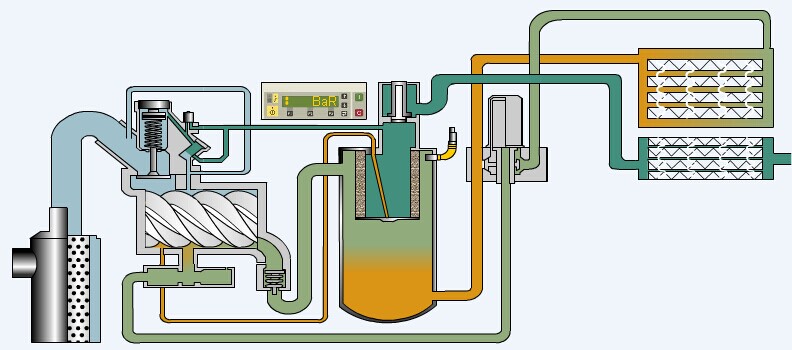

Screw air compressor flow chart

The first step is to inhale the air around the air compressor through the air filter to enter the compression host.

In the second step, the Yin and Yang rotors change the speaker’s volume by moving together.

At the same time, continuous oil injection in the cavity, lubrication, and cooling screw.

This creates a heated mixture of oil and gas.

In the third step, the oil and gas mixture enters the oil and gas separator tank through the exhaust check valve after heating and pressure boost.

In the fourth step, most of the oil in the main engine chamber is separated from the compressed air in the oil and gas separator and returned to the speaker for recycling after cooling.

In the fifth step, once the air in the oil and gas separator reaches the minimum pressure, the minimum pressure valve opens;

High temperature compressed air enters the aftercooler.

Step six, the compressed air temperature is cooled in the rear cooler to get the compressed air you need.