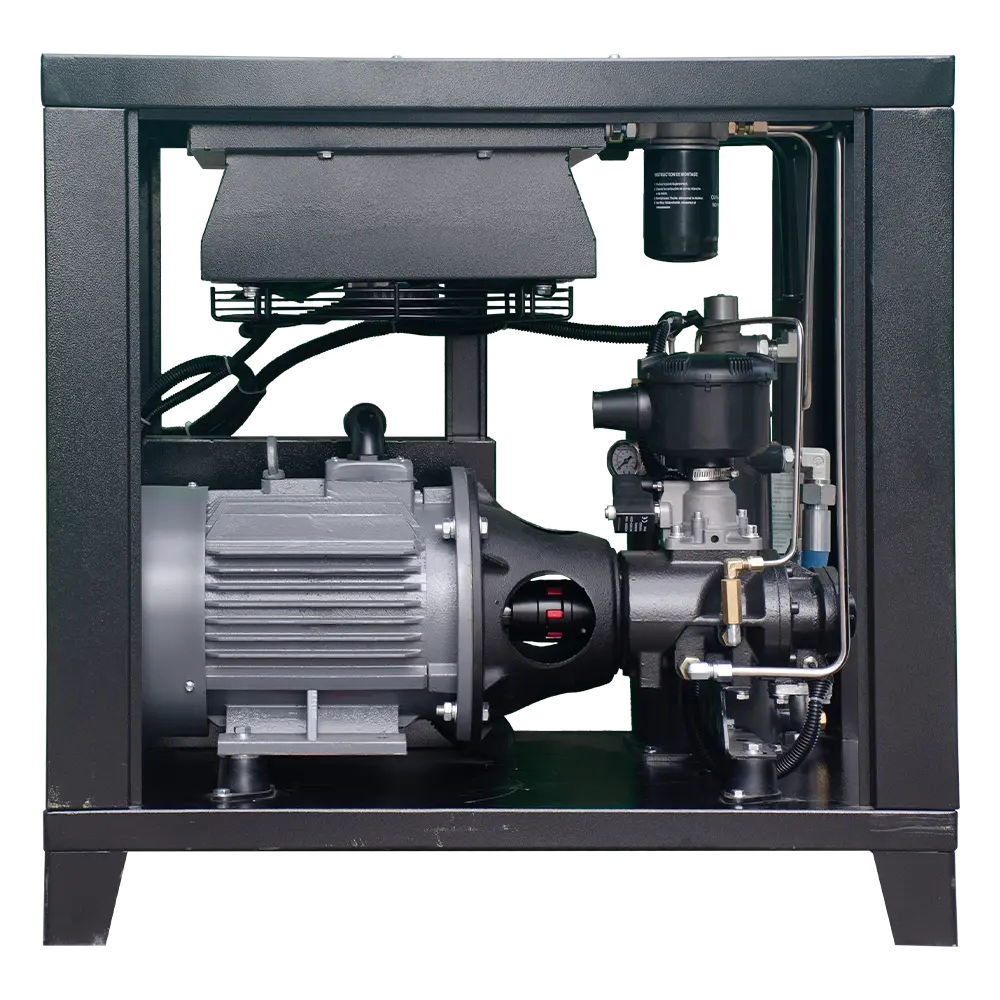

PM VSD Screw Air Compressor

Our Advantage

- Safe and Convenient

- Functions at extreme weather conditions

- They are designed to run tools that generate more power than

typical equipment - Screw type air compressor is easier to maintain

- They are good energy conservers

- They consume less oil than other oil-flooded air compressors

Product Description

German Technical Airend

1. The design idea of “large rotor, large bearing, low speed” is adopted to reduce noise and vibration and increase the life and stability of the host.

2. The tooth surface is processed by the German KAPP rotor grinder to create a high-precision rotor, which is the first guarantee of high efficiency and stability of the air end.

3. Adopt a new type of 5: 6 asymmetric rotor tooth shape, high-precision three-coordinate measuring machine for comprehensive measurement, increase the air capacity by 5% -10%

4. All imported quality bearings are used.

PM Motor

1. Large starting torque

2. Specialized motor for air compressor, imported quality bearings;

3. The combined use of this motor and permanent magnet rotor achieves soft-start and electricity saving of up to 50%.

4. Motor design is designed according to 1.2 coefficient;

5. Protection grade IP54, insulation grade F.

6. Permanent lubrication of the front and rear bearings of the motor without adding grease

Oil & Gas Separator

With bigger oli and gas separator and oil separator element, improving the initial separation efficiency , ,anking the oil content less than equal to 3ppm.

Inverter

The variable speed drive compressor works by maintaining a constant air pressure. The variable speed compressor will adjust the speed of the motor to meet the air demand of your production. A variable speed compressor can run on 100 percent flow or can fluctuate to less air flow. This will conserve energy and support the compressed air demand needs.

Technical Specification

| Model | E-10A | E-15A | E-20A | E-30A | E-40A | E-50A | E-60A | E-75A | E-100A |

| Free air deliver /Discharge pressure (CFM/PSI) | 1.2/0.7 1.1/0.8 0.9/1.0 0.7/1.2 | 1.6/0.7 1.5/0.8 1.3/1.0 1.1/1.2 | 2.5/0.7 2.3/0.8 2.1/1.0 1.9/1.2 | 3.8/0.7 3.6/0.8 3.2/1.0 2.8/1.2 | 5.2/0.7 5.0/0.8 4.5/1.0 3.8/1.2 | 6.8/0.7 6.2/0.8 5.6/1.0 4.9/1.2 | 7.3/0.7 7.0/0.8 6.0/1.0 5.6/1.2 | 10.0/0.7 9.1/0.8 8.5/1.0 7.6/1.2 | 13.5/0.7 12.6/0.8 11.2/1.0 10.0/1.2 |

| 42/102 39116 32/145 25/174 | 57/102 53/116 46/145 39/174 | 88/102 81/116 74/145 67/174 | 134/102 127/116 113/145 99/174 | 184/102 177/116 159/145 134/174 | 240/102 219/116 198/145 173/174 | 258/102 247/116 212/145 198/174 | 353/102 322/116 300/145 269/174 | 477/102 445/116 396/145 353/174 | |

| Compression stage | Single-stage | ||||||||

| Ambient temperature | -5–+45℃ | ||||||||

| Cooling mode | Air cooling | ||||||||

| Discharge temperature (0C) | Ambient temperature+15℃ | ||||||||

| Lubricant (L) | 3.7 | 10 | 10 | 14.5 | 15 | 20 | 20 | 45 | 45 |

| Noise Level (Db) | 62±2 | 64±2 | 65±2 | 66±2 | 68±2 | ||||

| Drive method | Direct driven | ||||||||

| Electricity (V/ph/Hz) | 380/3/50 | ||||||||

| Motor power (KW/HP) | 7.5/10 | 11/15 | 15/20 | 22/30 | 30/40 | 37/50 | 45/60 | 55/75 | 75/100 |

| Starting method | Inverter | ||||||||

| Dimension L*W*H (mm) | 880*650*830 | 1130*850*1140 | 1200*930*1260 | 1380*960*1300 | 1700*1090*1330 | 1830*1190*1380 | 1930*1370*1420 | ||

| Net Weight (kg) | 223 | 315 | 325 | 491 | 566 | 695 | 745 | 1090 | 1240 |

| Air outlet diameter (inch) | 3/4” | 1” | 11/2” | 2” | |||||