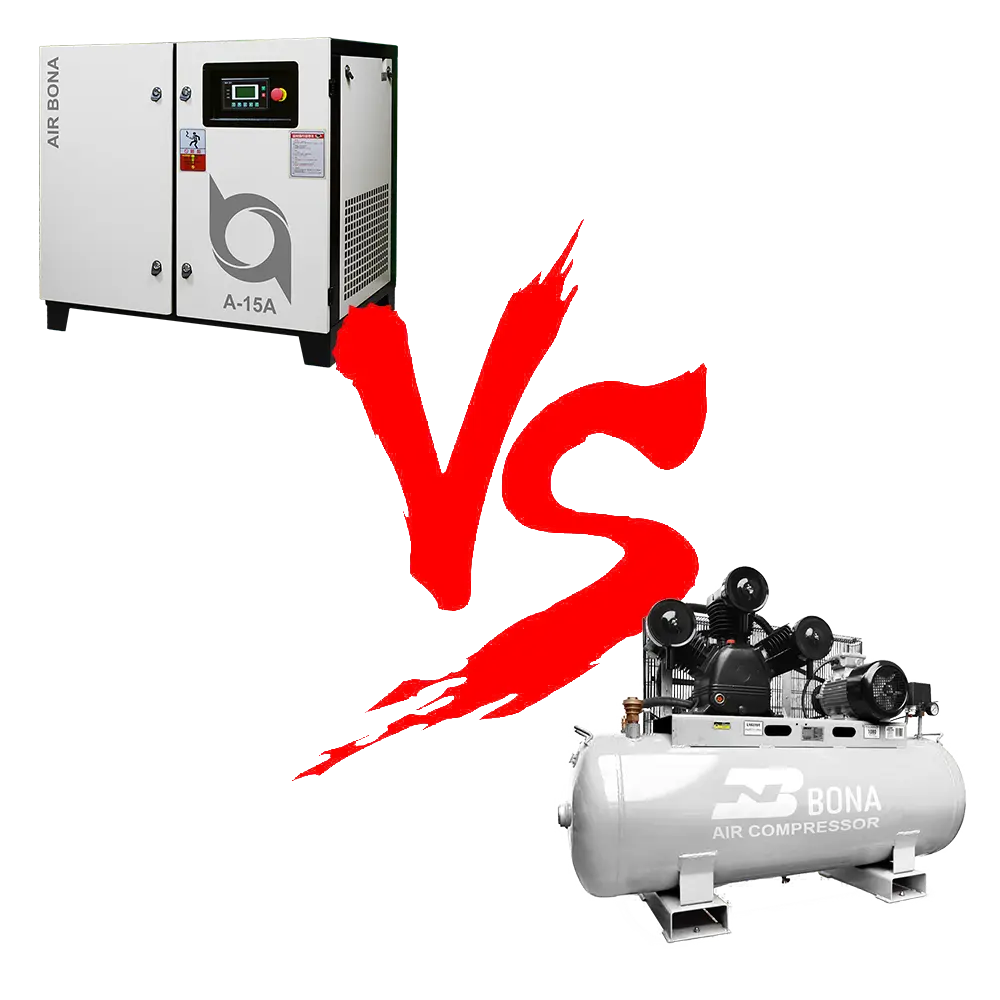

- Different structure

The organization structure of the screw air compressor is composed of an airend, electric motor, oil and gas separator, oil pipeline system, cooling system, gas pipeline system, and electrical control system.

Piston compressor comprises the air pump, cooling system, regulating system, lubrication system, safety valve, electric motor, and control equipment.

- Different features

The screw air compressor has the advantages of low vibration, no need to fix on the foundation with anchor bolts, low motor power, low noise, high efficiency, stable exhaust, and no wearing parts.

Under normal circumstances, the compressed gas of the piston compressor does not contain oil, and there is no need to add a degreasing device. The disadvantage of this machine is that the motor power is too large, the exhaust pressure is not stable enough, the exhaust temperature is high, the noise is too large, the maintenance workload is large, and the maintenance cost is high.

- Different faults

Screw Compressors

There are few failures of screw air compressors, and only need to do regular maintenance, replace the air filter, oil filter, oil and gas separator, etc., it can operate normally.

Due to incomplete oil scraping and poor sealing of piston air compressors, oil often runs to the packing device or even the piston ring, resulting in the compressed gas containing oil. In addition, the exhaust temperature is high, sometimes as high as 200 degrees Celsius. And the cooling is blocked, which makes the cooling effect poor; the piston ring is stained with oil, which is particularly easy to wear; valve flaps leak; cylinder wear, etc.

share to social media